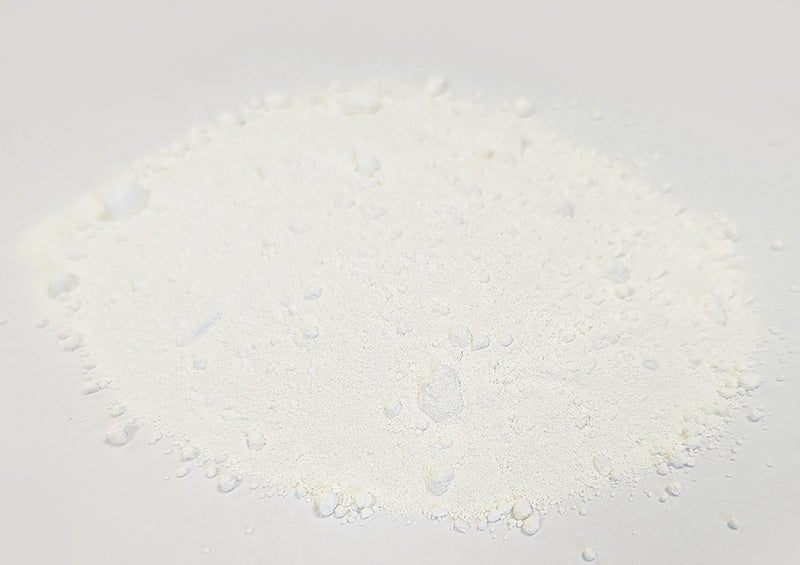

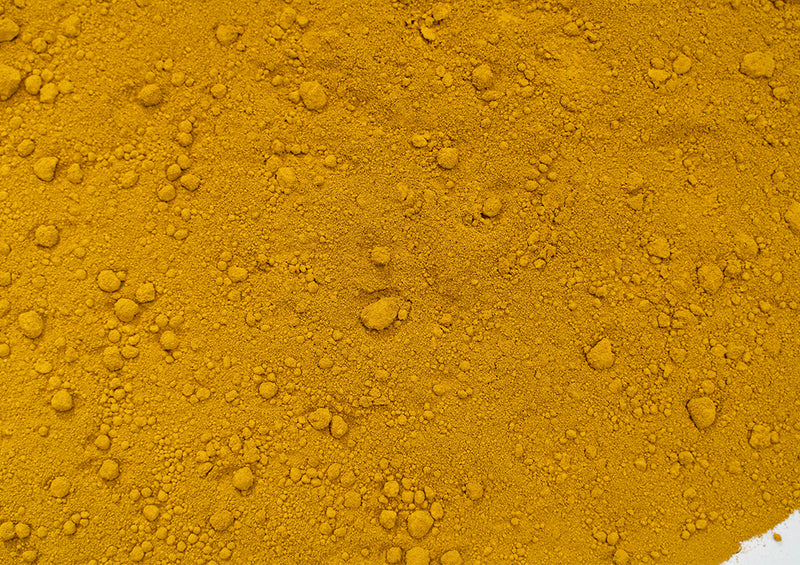

Pigments have been used across cultures since prehistoric times and remain a timeless choice for colouring breathable lime mortars and limewashes, particularly in the conservation and restoration of traditional and historic solid-walled buildings.

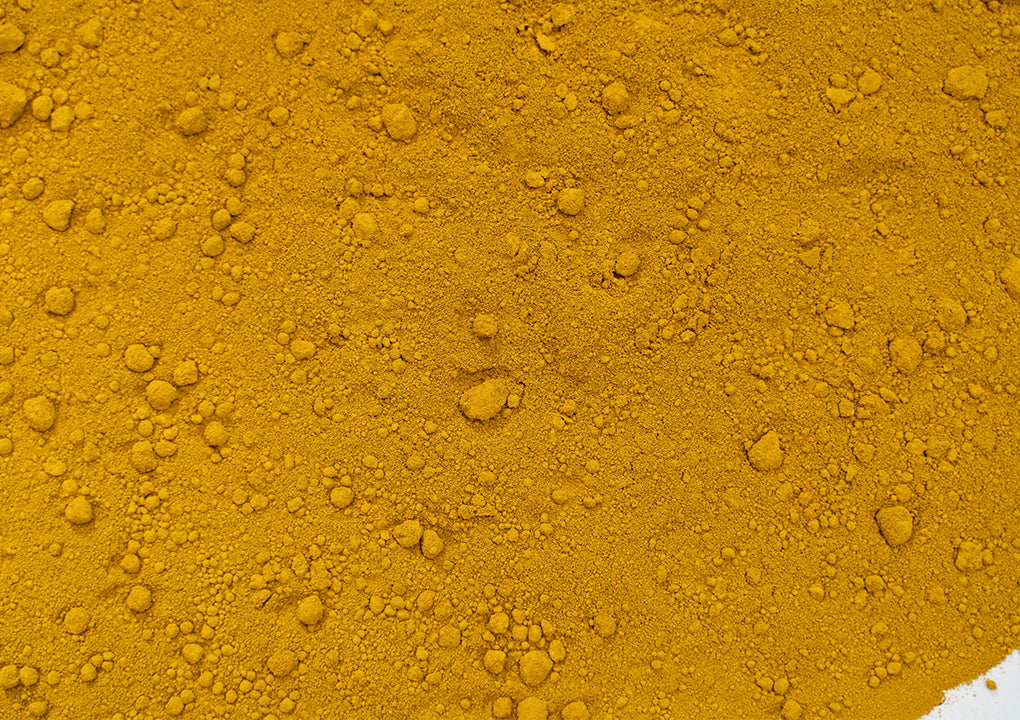

Our carefully curated pigment range includes natural, synthetic, and blended pigments selected for their exceptional quality, versatility, and popularity. Whether you’re aiming to recreate a classic Suffolk Pink or a warm Cotswold Yellow, our collection offers the tools to bring your vision to life.

Key Details:

-

Range: Multiple colours

-

Important Note: Colour perception is subjective and can vary between individuals.

-

Online Colour Disclaimer: The colours shown online are for guidance only. Actual shades may differ slightly due to the natural variation of materials and differences in screen resolution.

Application Guidance:

-

Mortars:

Carefully measure pigments before adding to the mix to maintain consistency across batches. Gradually introduce the pigment, ensuring it is fully dispersed to avoid clumping. For best results, pre-blend the pigment with a small amount of lime using a forced-action mixer (such as a plastering whisk) or mix it with hot water to create a slurry before incorporation.Keep in mind that variations in sand and lime proportions, especially when mixed by volume, can influence the final colour of the mortar. Additionally, note that pigment addition can affect mortar strength; we typically recommend a maximum of 10 kg pigment per tonne of lime mortar.

-

Limewash:

First, mix the pigment with a small amount of clean, potable water to form a paste or slurry. This step helps fully saturate the pigment, preventing dry clumps and ensuring an even, uniform finish. The amount of pigment required will depend on the chosen pigment and desired intensity of colour. As a general guideline, we recommend a maximum ratio of 20 parts limewash to 1 part pigment paste.